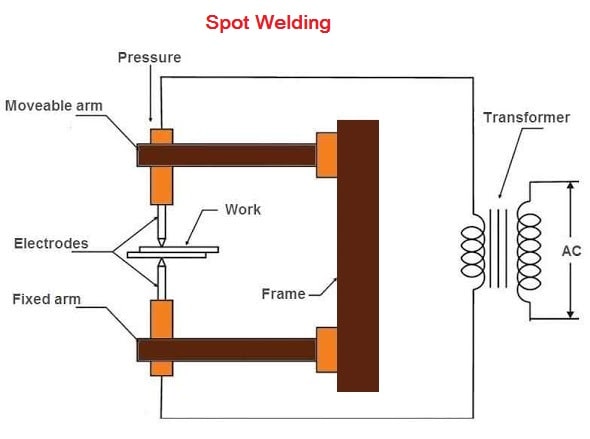

Spot welding or resistance spot welding is a type of electric resistance welding used to weld various sheet metal products through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current.

Spot welding machine working principle.

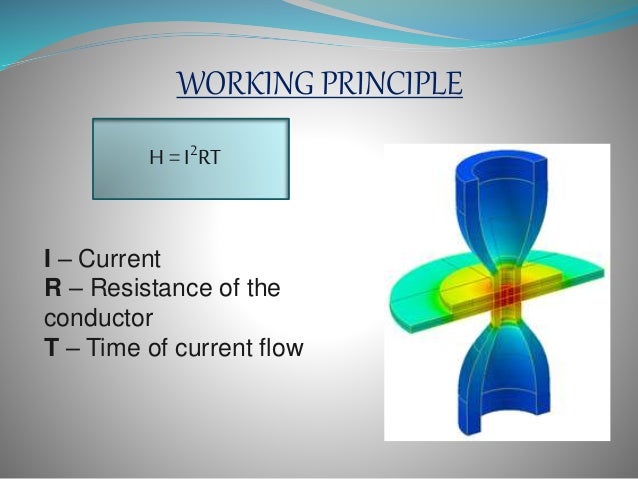

The working principle of resistance welding is the generation of heat because of electric resistance.

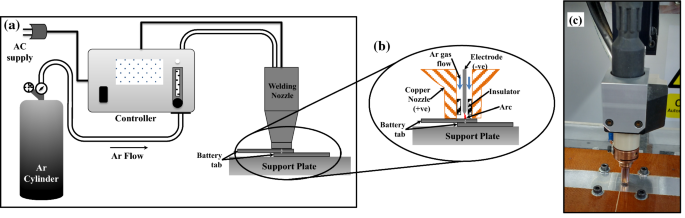

This is glowing electrical discharge among two electrodes throughout ionized gas.

In the last session we had discussed gas welding process and arc welding process and whereas in today s session we will discuss on resistance spot welding along with its definition construction working principle applications defects advantages and disadvantages.

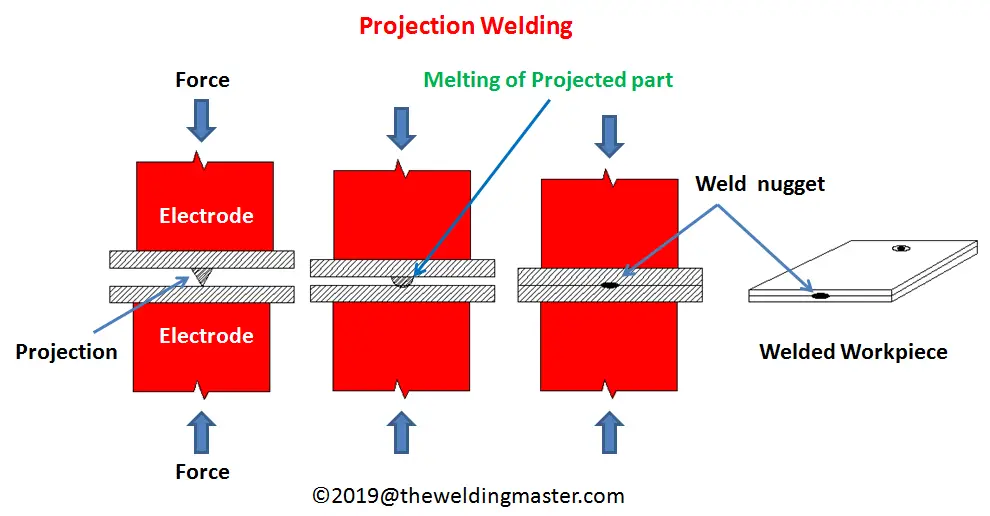

Introduction to spot welding working principle of projection welding introduction to spot welding spot welding is one of the type of welding processes.

The resistance welding such as seam spot protection works on the same principle.

The process uses two shaped copper alloy electrodes to concentrate welding current into a small spot and to simultaneously clamp the sheets.

Projection welding is one of the types of resistance welding and its working principle is quite the same as the resistance welding.

The working principle of arc winding is in a welding process the heat can be generated with an electric arc strike among the workpiece as well as an electrode.

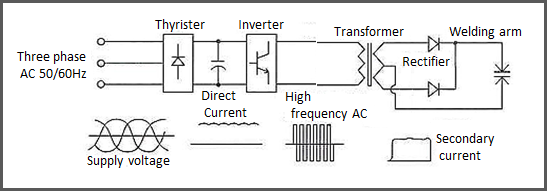

Usually spot welding as also other erw machines are automatic and work on the following weld cycle.

The only difference here is that projection or embossed joints are used for the welding purpose.

Today we will learn about resistance welding principle types application advantages and disadvantages.

Resistance spot welding operation is used for joining the plates of railway tracks fuel tanks domestic radiators etc.

Whenever the current flows through electric resistance then heat will be generated the same working principle can be used within the electric coil.

In the projection welding as per the name different projections are formed for effective welding.

Resistance welding is a liquid state welding process in which the metal to metal joint created in liquid or molten state.

It is a thermo electric process in which heat is generated at the interface surfaces of welding plates due to electric resistance and a controlled low pressure is.

Working principle of electric arc welding.

Resistance welding resistance welding working principle.